Future tech today

Incorporating new technological concepts into product designs increases their productivity, reduces total cost of ownership and improves safety and reliability. Sandvik Mining and Rock Technology’s tech insider is Patrick Murphy. In his role as president of Rock Drills and Technologies, he focuses on trends and incorporates these new concepts into product designs to increase their productivity, reduce total cost of ownership and improve safety and reliability. He shares his thoughts on the status of modern tech, how Sandvik uses it in its products and how these technologies will transform the way we work in the future.

Internet of Things

Definition: The interconnection, via the internet, of computing devices in objects enabling them to send and receive data. Industry example: Aircraft engines Sandvik example: Data Driven Productivity

- Hardware and software that collect and process large amounts of data from onboard equipment during the work process and the surrounding environment to provide customers with real-time actionable insights to improve their operations.

Four pillars of DDP:

- Predictive maintenance – providing maintenance to equipment before it’s required to ensure maximum uptime.

- Production management – maximizing productivity by removing inefficiencies in operation.

- Individual machine performance – measuring overall equipment effectiveness to maximize process efficiency.

- Operator efficiency – collecting data on operator performance to determine where product redesign or additional training may help improve safety or asset utilization.

Autonomous vehicles

Definition: A vehicle that is capable of sensing its environment and navigating without human input. Industry example: Self-driving cars Sandvik example: AutoMine

- Launched the first automation system for loading and hauling applications in 2004.

- Each vehicle knows where the others are using the traffic management system.

- Leverages the Sandvik navigation technology and algorithm.

3D scanning

Definition: Capturing real-world data to create a point cloud and convert it into a 3D model. Industry example: Measuring the volume of timber in a forest Sandvik example: Integration of scanning technology into underground development drill rigs Mounted on underground equipment, a 3D point cloud of the mining environment is created and can be used in a variety of ways, including:

- Navigating the drill rig so it knows where it is in the mine plan.

- Determining the volume of material excavated in the tunnel.

- Calculating against the mine plan whether there was overbreak or underbreak relative to the drift profile.

Patrick says: “This tech can measure where you are in the mine, volume in cubic metres of the material excavated and determine whether you’re on plan or not. All the data is stored onboard and, depending on the mine’s infrastructure, can be transmitted back to the control room or planner’s office via WiFi or storage media.”

Patrick says: “This equipment features patented charging-while-drilling technology that was born out of our research and development programmes, and regulates the charging process as the rig is working and connected to the mine electricity grid. With this technology, battery range and service life are enhanced.”

Green power systems

Definition: Electrical energy storage and transmission that limits pollution, providing the highest environmental benefit. Industry example: Battery electric vehicles Sandvik example: Sandvik DD422iE and Sandvik LH307B battery-trammed underground equipment

- Both the Sandvik DD422iE battery-trammed mining jumbo and Sandvik LH307B loader were designed to remove diesel particulate matter (DPM) from underground environments, mitigating health risks caused by DPM.

- They use either electricity from the grid or fully flexible battery solutions.

- With Sandvik DD422iE, downhill tramming does not consume power but tops up the batteries.

- Sandvik LH307B eliminates all exhaust emissions with all the independence and power of its diesel counterparts.

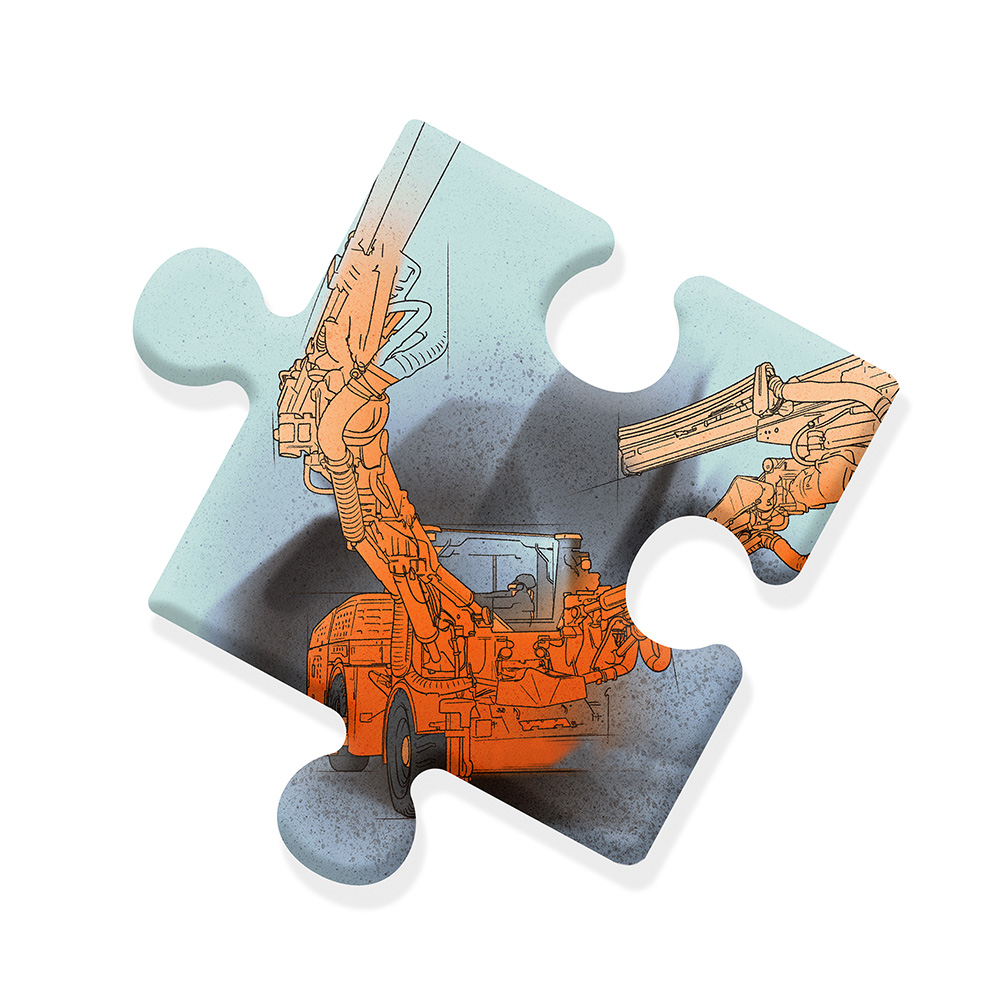

Piecing it all together

Here’s one vision of underground mining equipment’s future

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2017%2F05%2FIntelligence-Future-talk_1024x576.jpg)

Patrick says: “There is no science fiction about it. Our mission is to offer our customers optimal solutions designed to increase their productivity, reduce total costs of ownership and ensure reliability, efficiency and safety through high technology.”

- Battery powered, producing zero emissions.

- Sandvik DDP analyzes overall automation effectiveness and optimizes operations in real time.

- Onboard 3D LiDAR scanners with fast processing ability sweep the environment and enable real-time decisions based on current and predicted events.

- Fully autonomous vehicles that operate without restrictions, teach themselves and redefine how orebodies are mined.

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2017%2F05%2FIntelligence-Future-talk_1600x750-1.jpg)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F09%2FGarpenberg_1_edit-7979.jpg)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F08%2F1194_2.jpg)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2FSandvik_electric-surface-drill-rig-concept_01.jpg)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2Falpha340_hex_rod_with_bit_black_2022-1.tif)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2Fth665b_001.jpg)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2FLH518iB_03437.jpg)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2FRecycling_Factory_Stills1_2023.jpg)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2Fmodule-high-res_Frilagd.png)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2Fimage002-1.png)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2FGroup-4-2.png)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2FImage-1-1-e1684833065132.jpeg)

/https%3A%2F%2Fsolidground.sandvik%2Fwp-content%2Fuploads%2F2023%2F05%2FSandvik_Mo-I-Rana-3084_B-scaled.jpg)